Technology

Diaphragm Compression Molding Press

Diaphragm Compression Molding Press

What it does:

- 250–400 ton compression molding presses with vacuum fuse rubber and fabric under tons of force then heat-cure the finished part to achieve precise tolerances.

- Allows for the manufacture of high-quality fabric reinforced diaphragms in a wide range of sizes and materials.

Benefits for you:

- Increased production capacity

- Faster, shorter lead times

- Improved quality control

- USA manufactured diaphragms

- Custom diaphragm solutions with tight tolerances and material requirements

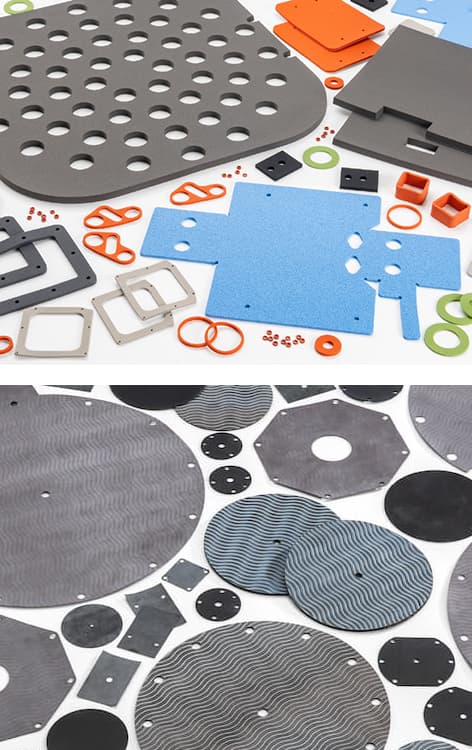

Flash Cutter

Flash Cutting

What it does:

- Flash cutting — more versatile and more flexible than die cut machines — is an automated die-less CNC Digital Knife Cutting System that uses reciprocating knives and rotating punches to fabricate flat silicone gaskets and flat diaphragms of a variety of rubber and fabric combinations.

- Flash cutting creates precise, custom shapes with clean edges and no cupping.

- The process involves inputting the desired shape using a computer-aided design interface.

- Precision tolerances are achievable on most materials.

Benefits for you:

- No tooling investment.

- Fast prototyping.

- Scalable service, offering flexibility for both small quantities and large production runs.

- By keeping the process in-house, we accelerate timelines, improve control, and help ensure quality while providing exceptional value to our customers, often saving you money.

Fecken-Kirfel Skiver

What it does:

- In-house, precise and efficient skiving/cutting machine.

- Sheets skived from buns can be supplied from 0.063” to 2.00” thickness, or buns can be skived into sheets using a customer’s own equipment.

- Four available ASTM-D-1056 hardness versions of the standard sheet, including one with enhanced fire-retardant additives necessary to meet UL94 V-0 specifications, and a second version with fluorosilicone sponge properties, meeting the requirements of AMS 3323.

Benefits for you:

- Lead times. The new skiving capabilities also in-house, converters will experience even greater expedition of their orders.

- The skiver has allowed Bellofram Elastomers to slash lead times for key products to converters to one week or less.

- The equipment also allows us to perform toll work, skiving product for other companies.